Long Lasting

The HDI Carbon 3D scanner uses a LED projector for long life span. The 3D scanner emits minimal heat which reduces scan distortion for repeatable 3D scanning results.

Engineered for flexible performance. Designed for portability.

What if you can have a powerful 3D Scanner that can easily adapt to scanning a variety of parts, while still easy to take with you on off-site projects? The HDI Carbon is your answer. It’s a crossover 3D scanner that combines flexibility and portability into one powerful system.

At the core of the HDI Carbon is its custom molded carbon fiber frame. The mount makes the entire system super flexible while being unbelievably lightweight.

The HDI Carbon gives you the flexibility to scan objects of various sizes. The system has 2 camera mounting positions on the carbon fiber frame to adjust the scanner’s diagonal field of view from 225mm to 600mm.

225mm Diagonal Field of View:

For scanning smaller objects.

600mm Diagonal Field of View:

For scanning larger objects.

The HDI Carbon 3D scanner uses a LED projector for long life span. The 3D scanner emits minimal heat which reduces scan distortion for repeatable 3D scanning results.

HDI Carbon delivers industrial-grade 3D scanning results using 2+ megapixel industrial quality machine vision cameras. The system generates more than 4 million polygons per scan at an accuracy of up to 35 microns (0.0014″) for a 225mm diagonal field of view.

See Scan Sample1.2 seconds per scan

35 microns (up to)

225 mm field of view

2+ million per scan

4+ million per scan

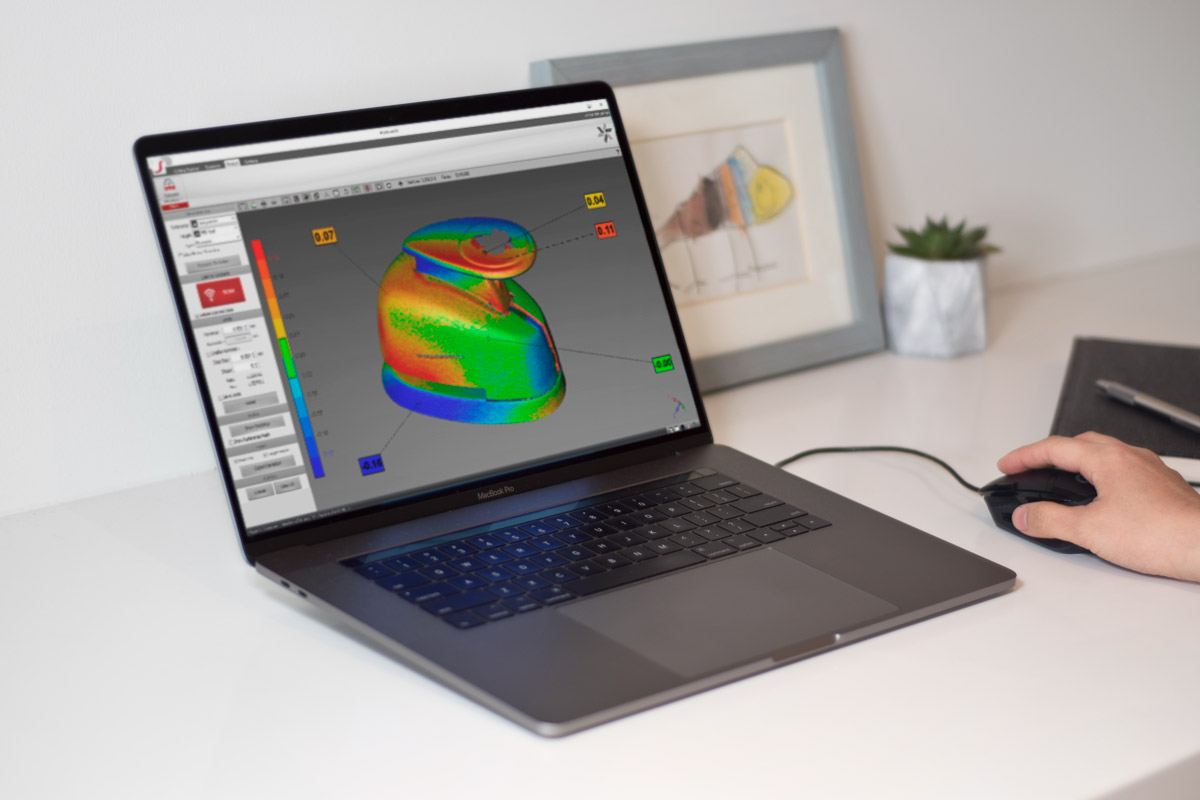

Challenge: A power plant equipment manufacturer produces large impellers. Stainless steel is an expensive material to waste when the impellers are first produced as castings and then later machined of excessive material to create the finished components.

Solution: HDI Carbon, together with 3D inspection software, helped pinpoint exactly the areas of wastage. The findings empowered the client to take corrective actions that resulted in tremendous material cost savings of approximately $600 USD per component.

Discover How

A performance driven 3D scanner shouldn’t be limited to only scanning in one location. For maximum portability, the scanner comes with its own travel case to take with you, wherever you need it. All the components fit nicely inside the case for added protection. Rest assured that your equipment is protected. It’s crushproof, watertight, and dustproof.

Proprietary 3D scanning software FlexScan3D has aligning, merging, and hole filling capabilities to transform 3D scans into a complete digital 3D model. It also comes with basic inspection tools for deviation analysis.

PLY, OBJ, STL, ASC, FBX

Great for applications including: