How to Prevent Buyer’s Remorse

When Buying a 3D Scanner

Are you in the process of evaluating which is the best 3D scanner to buy? In the second part of his series, Tom O’Mahoney wants to help you find a 3D scanner that you will be happy with post-purchase.

Tom specializes in 3D imaging for cultural heritage, physical anthropology, and palaeontology.

It is an unfortunate story I hear far too often. The person who heads a lab is granted funding for a 3D scanner purchase. He/she is attracted by the inexpensive price tag thinking that all 3D scanners are alike and any one of them should be capable of doing the job.

Often, the funds are only offered for a very limited time frame. It focuses the mind on price, rather than the needs of the lab. Instead of conducting thorough research, the final decision is to purchase a low-cost 3D scanner which is universally panned by the end users from the beginning of use.

Once the 3D scanner is purchased and the lab starts using it for actual work, the initial excitement of buying a 3D scanner fades and buyer’s remorse sets in. The quality of the 3D scanner output isn’t good at all. The poor quality makes alignment and stitching of individual 3D scans into accurate digital 3D models difficult, if not impossible. In some cases, the 3D scanner can’t even perform the scans for the type of objects they intended to scan.

Now they are stuck with a piece of equipment that can’t do the job. To make things even worse, they used up the budget so they can’t purchase another 3D scanner that can actually do the work.

I want to prevent you from making this common mistake. This scenario isn’t limited just to academic purchases. It also applies when businesses and organizations go through a similar process of buying a 3D scanner.

The price of a low-cost 3D scanner might look attractive at first glance. However, this guide explains why professional 3D scanners are better investments in the long run even though they might cost more upfront compared to low-cost 3D scanners.

We’ll highlight four factors that are crucial to look at when buying and evaluating 3D scanners so you can get the best 3D scanner you will be truly satisfied with.

- Factor #1: Quality of Scan Data Output

- Factor #2: Time

- Factor #3: User Experience

- Factor #4: Support

Factor #1

Quality of Scan Data Output (Resolution, Accuracy, Repeatability)

Resolution, accuracy, and repeatability play an important role in affecting the 3D scanner price. In most cases, you get what you pay for. For example, an expensive 3D scanner is priced this way typically because it’s tied to the quality of the scan data it produces.

When discussing about the quality of the raw output of a 3D scanner (or 3D scan data), these three terms come to mind.

- Resolution: The number of 3D measurement points a 3D scanner can collect in a single scan.

- Accuracy: How a single measurement point captured from the 3D scanner relates to the real value. In the real world, there is always uncertainty in a measurement. It’s how much uncertainty you are comfortable with that is the key. If you require high accuracy, this means the 3D scanner you need would be more expensive compared to one that is not as accurate.

- Repeatability: How close can a measurement device (i.e. a 3D scanner) can get the same results every time.

How Quality Affects 3D Scanner Price

Even professional grade 3D scanners can be categorized into three levels: entry-level, mid-tier, and high-end 3D scanners.

| Consumer Grade | Professional Grade | ||

|---|---|---|---|

| Low-Cost < $5,000 |

Entry Level > $5,000 |

Mid-Tier ~$10,000-$25,000 |

High End > $25,000 to $100,000+ |

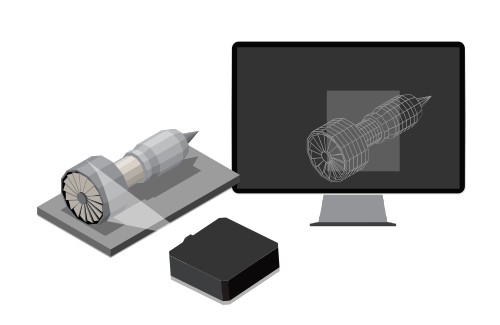

Professional 3D scanners are capable of high resolution, accuracy, and repeatability because they go through intensive R&D to make sure their measurement devices are built for demanding industry applications such as quality inspection and reverse engineering.

For example, professional 3D scanners are usually built in accordance to machine vision accuracy standards: either pre-calibrated to a known standard, or the capability for end users to tune calibrations using known size artefacts. All HDI Compact 3D scanners from Polyga are calibrated to this standard, which ensures high accuracy and repeatability.

That’s one of the reasons why they cost more. If you need a 3D scanner where accuracy and repeatability are important, then getting a professional 3D scanner is a must.

High accuracy, high repeatability 3D measurements

You can get a 3D scanner that gives you high accuracy and low repeatability or a low repeatability and high accuracy. Both of these cases are not ideal because the measurements can’t be trusted, especially when you are using it for work.

Low accuracy, high repeatability 3D measurements

Low accuracy, low repeatability 3D measurements

Professional Versus Low-Cost 3D Scanner

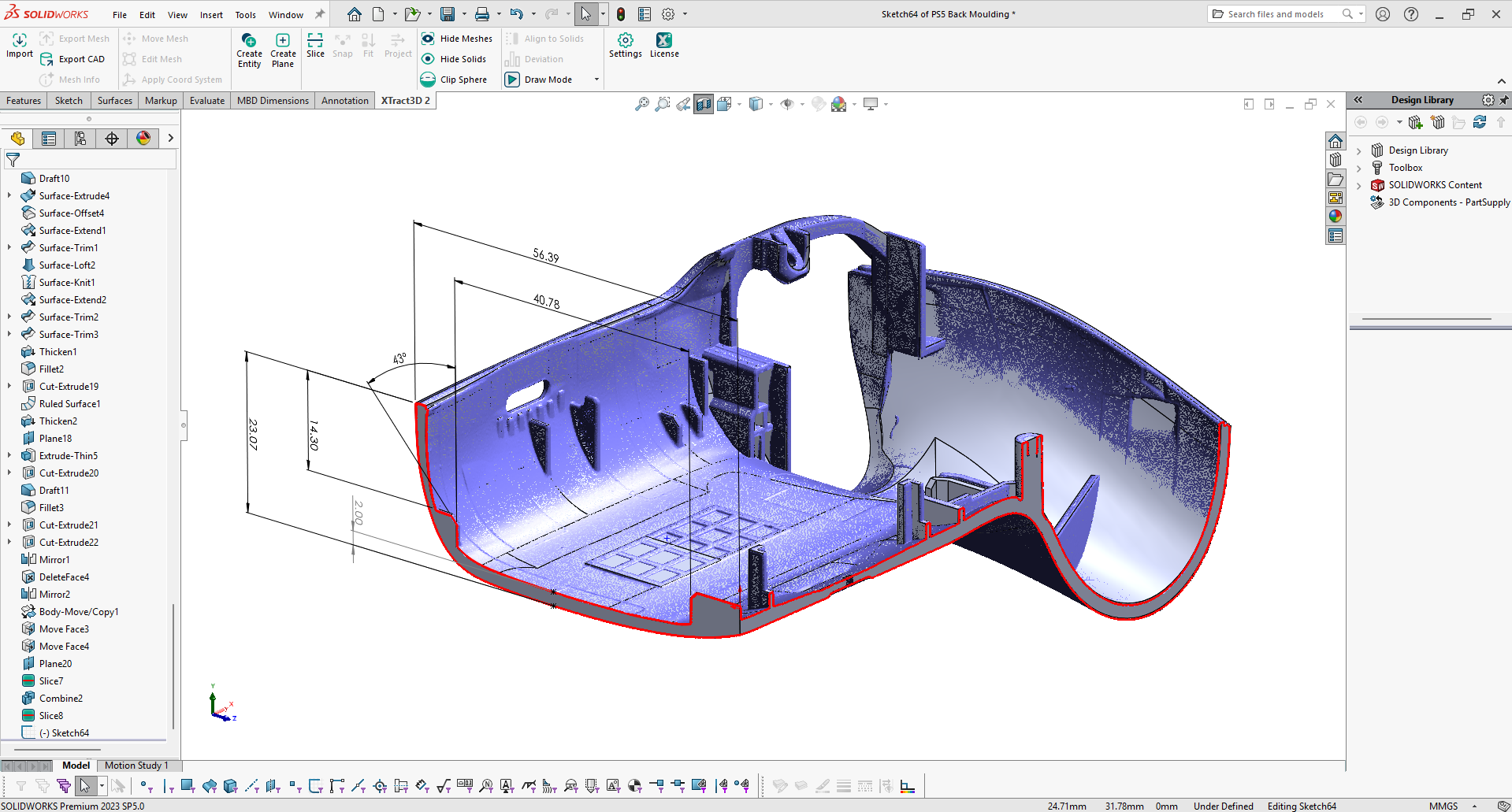

To illustrate the quality difference between a professional 3D scanner versus a low-cost 3D scanner, I’ve scanned a small monkey skull using the HDI Advance 3D scanner and the NextEngine 3D scanner.

| Professional 3D Scanner HDI Advance R3x |

Low-Cost 3D Scanner NextEngine |

|---|---|

| View it on Sketchfab. | View it on Sketchfab. |

|

To make it a fair comparison, both models were processed on the same laptop-a quad core i5 with 16GB RAM and a 4GB Nvidia 960 graphics card. They were both also scanned under normal office lighting. |

|

If you view each model in fullscreen mode, you can see the HDI Advance 3D scanner captures much more detail of the object, including small sutures and surface texture of the bone. In addition, the HDI system captures cleaner data, whereas the low-cost 3D scanner captures more noise around the teeth in the model. In this test, I deliberately set the HDI Advance 3D scanner to a wider field of view than is ideal for this object.

More triangles in your mesh don’t necessarily mean higher quality or resolution. Often, lower-quality 3D scanners have poor triangulation algorithms, which result in models becoming unnecessarily large, with noise being introduced into the model as a consequence. This, in turn, makes your data harder to work with. Professional scanners avoid this by using smarter triangulation routines from the raw data.

To illustrate this point, scans from the low-cost 3D scanner took more than 2 hours to scan and to post-process. I had to put the scan data output through a separate advanced post-processing software to create the model. Meanwhile, the professional 3D scanner took only about 15 minutes for the entire process from scan to output and it didn’t need additional software to complete the task. Sometimes, it pays to prevent frustrations and headaches that can be caused by technological hindrances.

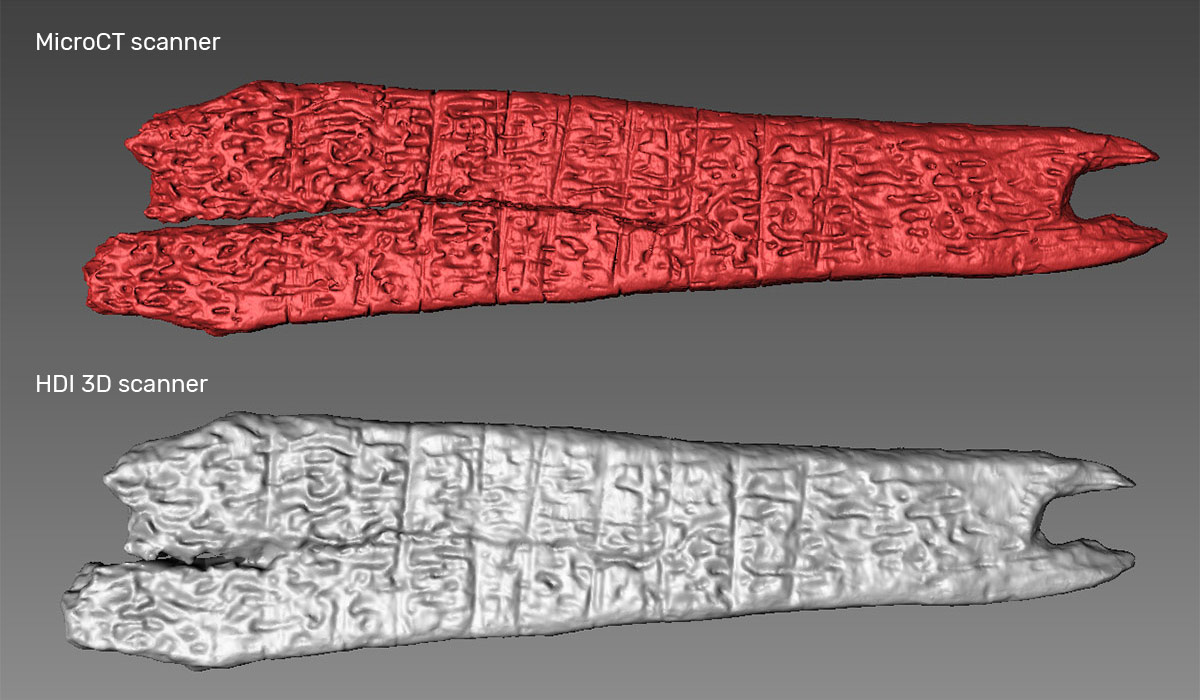

Professional 3D Scanner Versus MicroCT Scanner

I’ve also done a visual comparison of scans between the HDI Advance 3D scanner compared to a MicroCT scanner. The image below is a bone implement, thought to be a fishing weight from a cave in Derbyshire, UK. I’ve scanned this using a Nikon XTH225 MicroCT scanner (top image) and the HDI Advance R3x 3D scanner (bottom image).

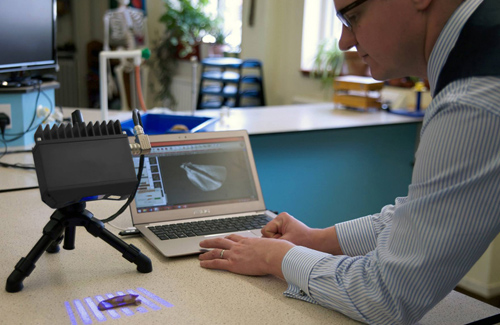

As you can see, both scans show incredible detail. The advantage of the HDI Advance R3x 3D scanner is it is a portable 3D scanner so you can take the system to the object for scanning.

On the contrary, a MicroCT scanner costs hundreds of thousands of dollars, is fixed in one place, and has hefty maintenance costs. You are often charged for using the machine as well.

A professional 3D scanner is about 1/10th of the cost of operating a MicroCT. Therefore, the cost of 3D scanning is much lower compared to a MicroCT scanner. A professional 3D scanner offers great value for the price you pay.

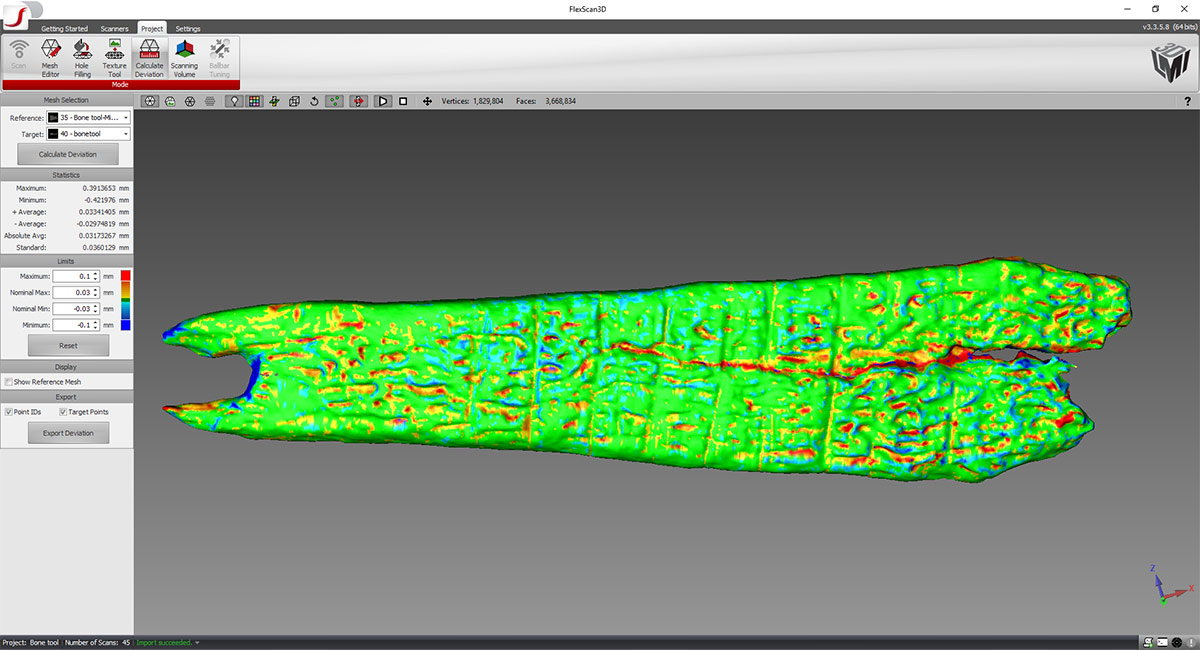

Deviation analysis of the two scans using Flexscan’s 3D scanning software built in tools shows that the differences between the two scans are minimal. The high accuracy scans produced by the Polyga series of 3D scanners can be comparable to MicroCT. On average, the scans were less than 35 microns different. This is excellent for producing accurate replicas, as few printers will have an accuracy below 100 microns.

A recent research paper found the HDI Compact 3D scanner to be a more than acceptable replacement for MicroCT for 3D scanning large collections of small animal skulls. A low-cost 3D scanner would not be any good for this type of detailed work.

Factor #2

Time

I remember during my PhD, I sent curators my estimated timings for 3D scanning workflows and they were sceptical. At two institutions, I went home over a week early as I had beaten even my estimates. At another, I was able to enhance my experience at the museum by joining in new collaborations and having in-depth discussions with curators about fossils in their collections. With a low-end 3D scanner, I wouldn’t have had the time or mental space to do this!

From my experience, here is the time it takes from 3D capturing to post-processing using two different types of 3D scanning systems:

| Time | Low-cost Laser 3D Scanner |

Professional HDI 3D scanner |

|---|---|---|

| 3D Capturing (6 scans, rotary capture) |

30-35 minutes | 5-10 minutes |

| Clean up Scans | 10 minutes | 2 minutes |

| Alignment of Scans | 15 minutes | 2 minutes |

| Merging of Scans into Digital 3D Model | 2 minutes | 1 minute |

| Total Time it Takes from Scan to Model | 1 hour + | 10-15 mins |

Time is money. Investing in a professional 3D scanner with faster capture times and more sophisticated 3D scanning software save you a lot of money, even in the short term. Especially if you capture a lot of data off-site.

We all wish we have more time in the day. Clunky 3D scanning software also contributes to time wasted. If you have better user-friendly software that doesn’t hinder your work, it will improve efficiency.

Just imagine if you have to scan in volume. This effect would be magnified by adding even more time when using a low-cost 3D scanner. The photo below are the objects I managed to scan and process in 90 minutes using a professional 3D scanner. This was the time that it took the low-end 3D scanner to scan just the skull!

View the entire collection in 3D on Sketchfab.

Think how much money is wasted by using inappropriate tools. This applies for any type of job: design, research, or inspection. If you want to scan objects or parts in bulk, you need to get the right 3D scanner to do this type of job.

Want to see what 3D scanning has to offer?

We can answer any questions on how the technology can benefit the way you work.

Ask Us!Factor #3

User Experience (Usability and Software)

Low-cost 3D scanners have software that treats the whole process like a ‘black box’. Users have very limited opportunities to change the parameters under which they scan objects or process the data. While this can be useful for people who are new to 3D scanning, this lack of control means that you rapidly come up against challenges, as the software has been optimised for a narrow set of use cases.

Another area in which professional 3D scanners distinguish themselves from low-cost 3D scanners is both the ease of use and customizability of the 3D scanning software that comes with the scanner.

Some of these restrictions include:

- Inability to change exposure levels

- Post-processing of scans such as hole filling are all totally automated

- There are no advanced features such as texture reprojection or deviation analysis

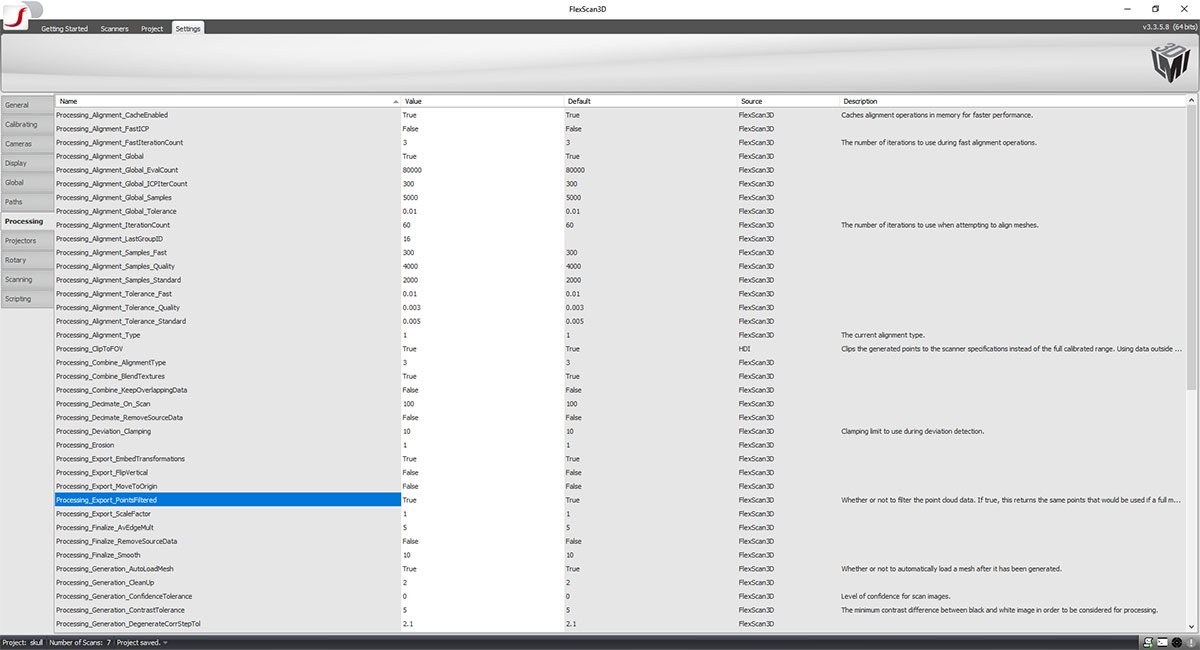

More advanced programs also enable scripting, which can help you to automate aspects of your work. This makes things less labour intensive and more repeatable.

Here’s an example of some of the settings that advanced users can tweak in Flexscan3D software included with the HDI 3D scanners.

Factor #4

Support

If you get a 3D scanner that’s not from a local reseller, it would be difficult to get help in order to resolve issues and challenges when you need it. Even if you buy from a local reseller, you need resellers who know what they are doing, not those who are just pushing products and have little knowledge. If they carry a lot of products sometimes they don’t have solid expertise in all the 3D scanners they sell.

I have found with professional level 3D scanners, the level of user support is much higher and the local service agent will be someone who does 3D scanning on a daily basis. They really understand the ins and outs of your product and can often save you a lot of money in call outs by suggesting fixes which have worked for them in the past. You can contact your 3D scanner supplier to see if they have local representation in your area.

The Takeaway

Your use case should drive the 3D scanner you buy.

Why are you digitizing physical objects into 3D models?

| Application | Important Factor(s) |

|---|---|

| Reverse Engineering | Accuracy |

| Quality Inspection | Accuracy and repeatability |

| 3D Printing | Quality of scans is limited to how good your 3D printer can print so quality is not always overly important |

| Research/Scientific Measurement | Accuracy and repeatability are important |

| 3D Visualization | Resolution is important |

We’re not saying that low-cost 3D scanners are bad. Like everything else, they have their place. They are good for tinkering (ie. for proof of concept) or if you want to explore what 3D scanning has to offer without fronting up too much investment (ie. lightweight type of work).

If you need a 3D scanner for heavy-duty work, you should look seriously into professional 3D scanners. Since there are different types of professional 3D scanners, you still need to be diligent in knowing that the system you ultimately choose is going to do what you want.

Professional grade 3D scanners come in a variety of formats:

- If you are looking to scan lots of different types of objects, you should look into a 3D scanner with a flexible field of view such as the HDI Advance or Polyga Carbon series of 3D scanners.

- If you are scanning mainly the same size and type of objects, fixed calibration 3D scanners such as the Polyga Compact are very useful. Just plug it in, install the 3D scanning software that comes with the scanner, and it’s ready for use. Fixed calibration scanners are also often good for working in harsh environments as they are often IP67 rated or similar.

I have used both types of 3D scanners with great success in remote Northern Kenya.

A Final Word Of Advice

You should really do your research and get some input. Ask around: you probably know someone or your connections know of someone who has already purchased a 3D scanner for your use case. See what they would recommend. They might recommend the same scanner or may have had buyer’s remorse and now know which 3D scanner they would purchase the next time they have funding.

There are times when the purchaser of the equipment is NOT the end user. You should get feedback from your team to see what they would recommend as they will be using the 3D scanner.

Equipping yourself with relevant information on equipment and knowledge of your likely uses will really help you make the most informed decision.

I hope that this guide will help you find the 3D scanner that ultimately gives you the most satisfaction, in terms of user experience and getting the best quality scan data.

If you have any questions or concerns, please feel free to contact me.

Best regards,

Tom O’Mahoney

School of Life Sciences

Anglia Ruskin University

Email: omahoney3dconsulting@gmail.com

Website: sites.google.com/site/tomomahoney

Which 3D Scanner Is Right For Me?

If you would like to speak to us regarding how to best integrate 3D scanning for work, please contact us at contact@polyga.com.