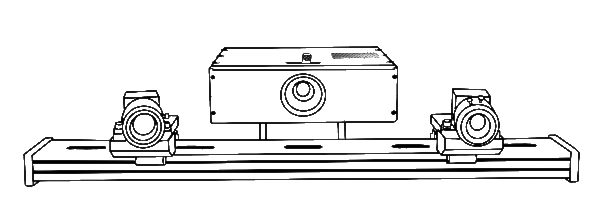

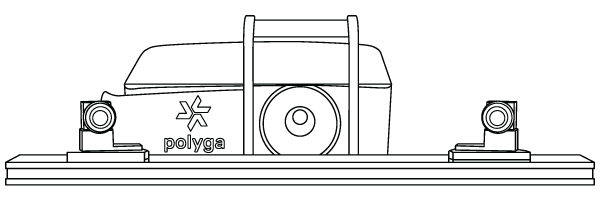

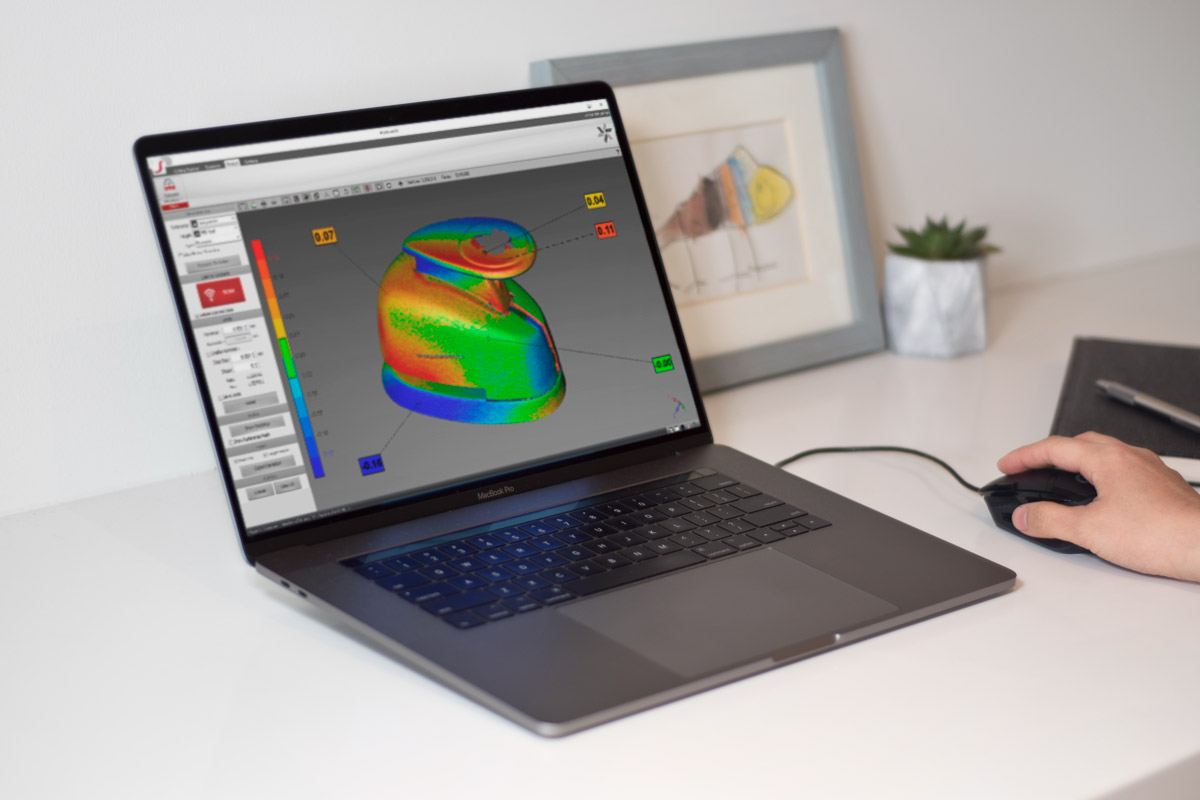

What if you can have a professional 3D scanner that has the power to easily adapt to your scanning needs?

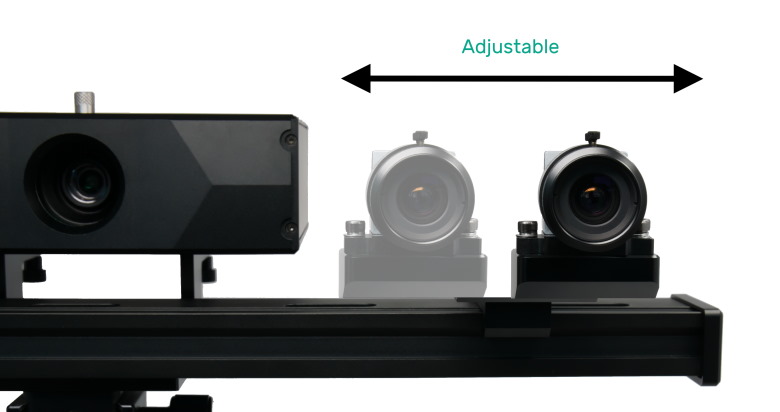

The Polyga Carbon is your answer. While other systems can be restrictive in its ability to only scan similar sized objects, the Polyga Carbon is different. What makes it special is its ability to scan objects of different shapes and sizes simply by changing the observable area (field-of-view or FOV). Get the versatility you need all in one system.