At Polyga, we always advocate that there’s no one tool or device that can do it all. You need to use the right tool for the job. With more than a decade of developing structured-light 3D scanners, we’re happy to announce Polyga has expanded its product line with the launch of the company’s first optical coordinate measuring machine (CMM), MeasureXL. This 3D measurement system makes it simple to set up and quickly probe 3D measurement points off the contours of a part.

Why We Developed MeasureXL

The reason behind the creation of MeasureXL is that there are times when our customers just need to take a few measurement points quickly for work. As a result, we decided to broaden our product line by developing a portable CMM.

MeasureXL was developed in partnership with our North American distributor, GoMeasure3D. Their team has more than 20 years in the 3D scanning and CAD industry. It helped us improved the product to create a better, cost-effective handheld optical CMM.

Measure with Freedom

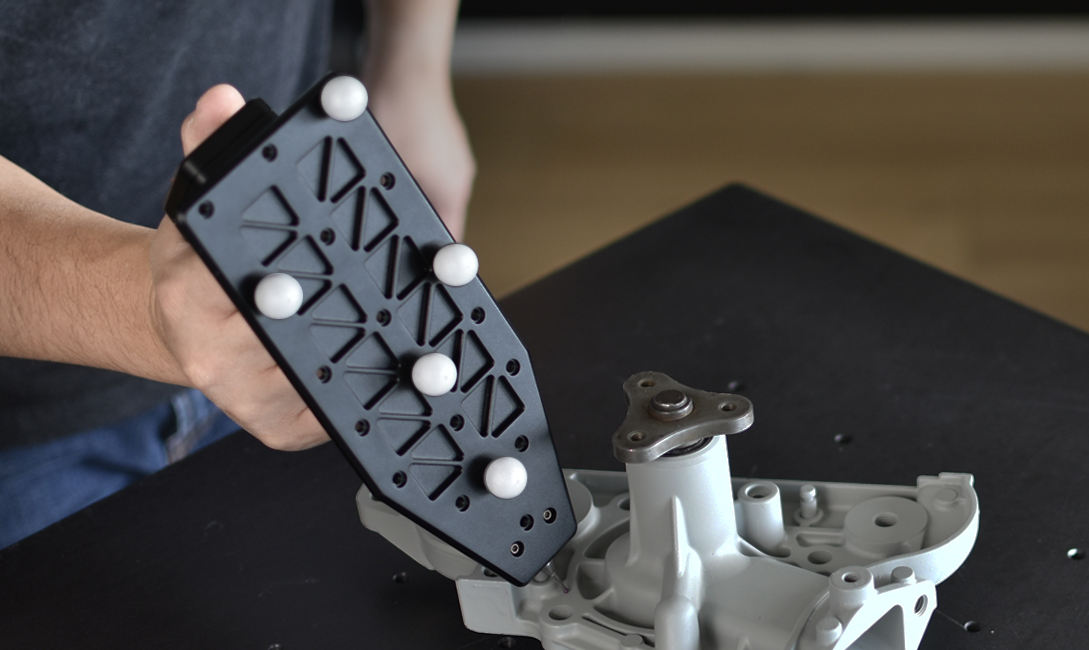

MeasureXL portable CMM includes a wireless probe and a factory-calibrated optical tracker for an out-of-the-box accurate tracking experience. The 3D digitizer measures wirelessly—giving you the freedom to measure. It doesn’t have any movement restrictions compared to traditional portable CMMs with articulated arms. It’s also very responsive. Use the probe to pinpoint any measurement point (XYZ) in the three-dimensional space and get the results instantly.

Using MeasureXL’s wireless probe, take measurements freely compared to traditional portable CMMs bounded by articulated arms.

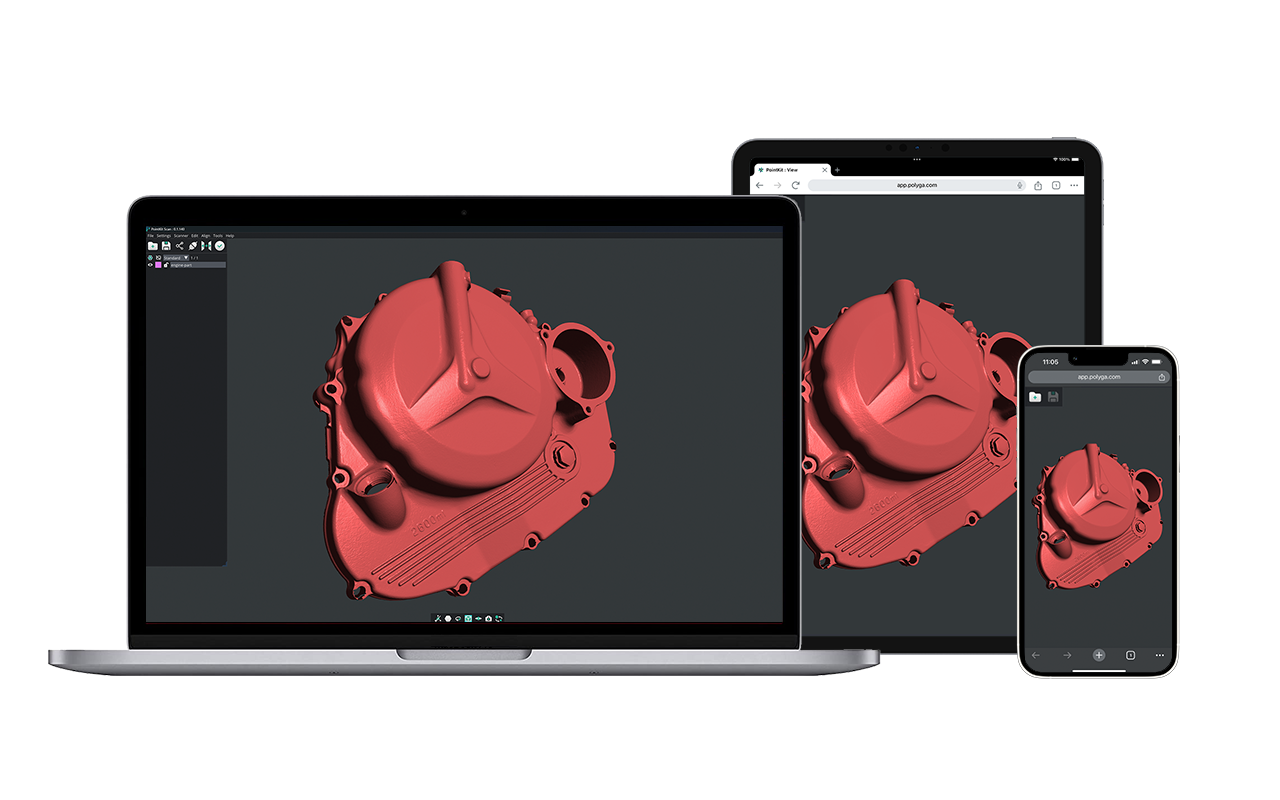

MeasureXL includes its own proprietary software, giving you the ability to measure and create all types of 2D geometry (arcs, lines, and splines), 3D geometry, as well as angles, distances, and points.

Measure Large Objects

As its name suggests, MeasureXL has a large working volume so you have plenty of space to work in.

The portable CMM has a flexible measurement range for measuring objects from the size of a baseball to a car dash.

Integration with Rhino 6 for Windows for Reverse Engineering

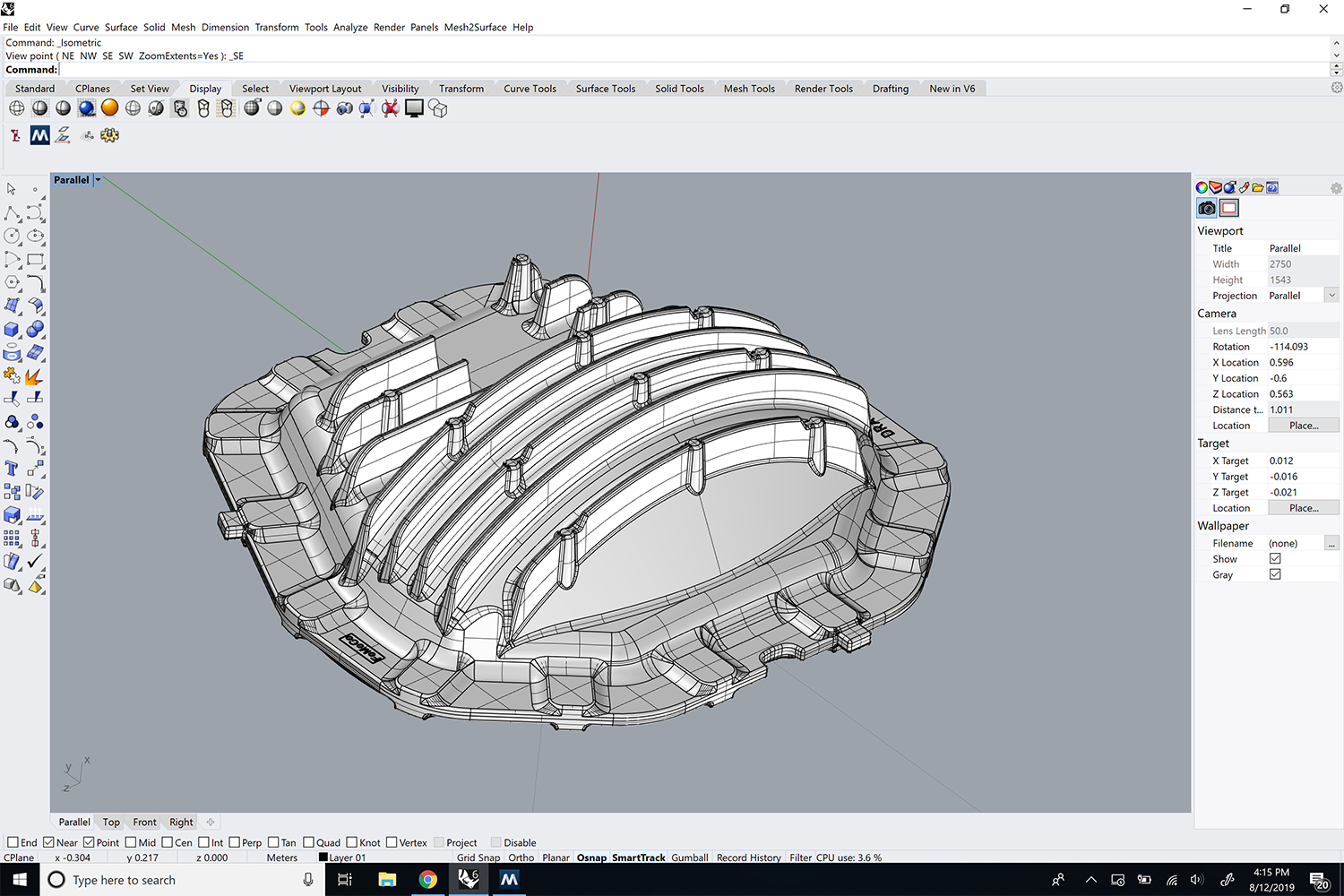

Traditionally, full reverse engineering packages that include hardware and software are quite expensive. What’s special about MeasureXL is that it is fully integrated with Rhino 6 for Windows CAD modeling software to create an affordable Scan to CAD solution. Data taken from MeasureXL shows up in real-time inside Rhino 3D to create accurate CAD models in lesser time than designing them from scratch.

Measurements points from MeasureXL can be used directly inside Rhino to create a CAD model.

Probe measurement points off organic surfaces with MeasureXL and use them inside Rhino. Here is a video demonstration of the process:

Learn more about MeasureXL by reading the press release or view the product page below.