3D Scanning Trends for 2019

The start of the new year always brings so much excitement when it comes to figuring out what’s ahead for technologies this year.

What are some 3D scanning trends we predict will gain in popularity this year?

-

Automation will drive work efficiency

As the 3D scanning market hits maturity, people are now expecting more out of professional 3D scanners. Systems need to be performance-driven, cheaper, and ultimately faster.

As with any technology, it goes through several phases of technological improvements.

3D scanning technology has evolved in the follow ways:

- The basic 3D scanning workflow is streamlined in each step, from capturing 3D scans to post-processing of scans into a digital 3D model

- Continuous improvements to 3D scanner’s hardware components (e.g. imagers) enhance performance

- 3D scanning software algorithms optimized processing speed

So what is the next biggest obstacle when it comes to speeding up the 3D scanning process?

At times, the workflow can be bogged down by repetitive manual tasks. As a result, there’s a stronger demand to fully automate the complete 3D scanning process.

Automation is key to reduce or eliminate human involvement. To have a fully automated workflow would be one where the entire process is completely done with a press of a button.

A good 3D scanning automation solution should be good at:

- Cutting down the amount of time it takes from capturing a physical object into a complete 3D model (Efficient)

- Ability to get clean, high quality output in terms of resolution and accuracy every time (Effective)

More and more scanners are becoming available in the market that will completely automate the 3D scanning process to save time.

Automation options include:

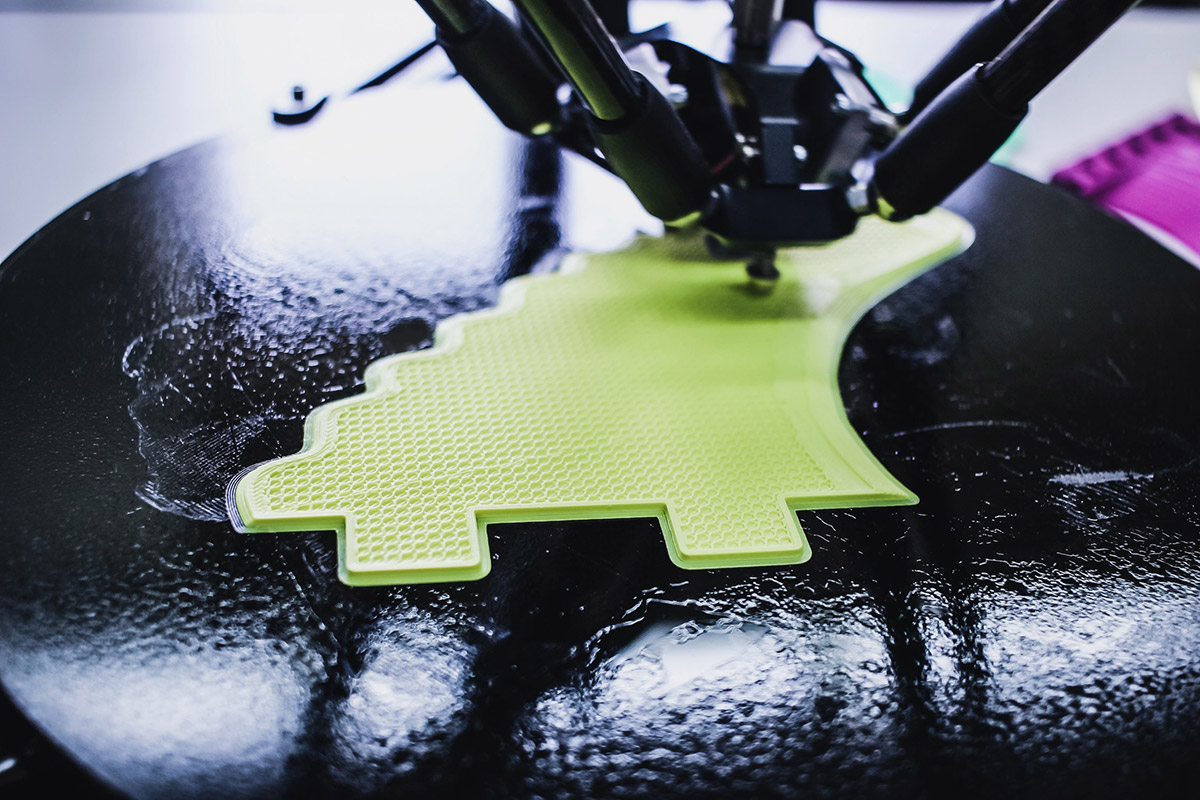

- mounting 3D scanners on robot arms

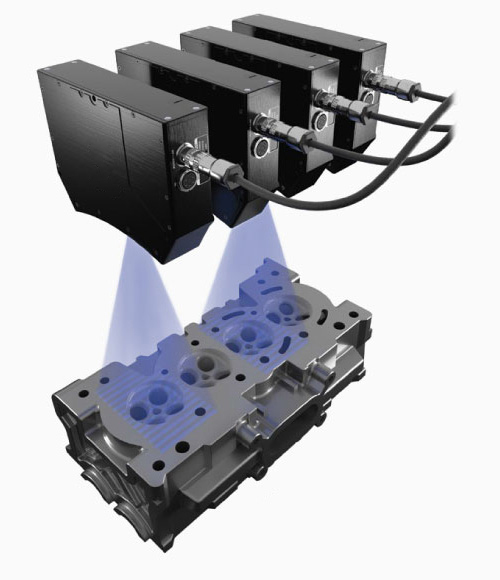

- using multiple 3D scanners to form an array

- using a multi-axis motion stage alongside a 3D scanner to rotate the object

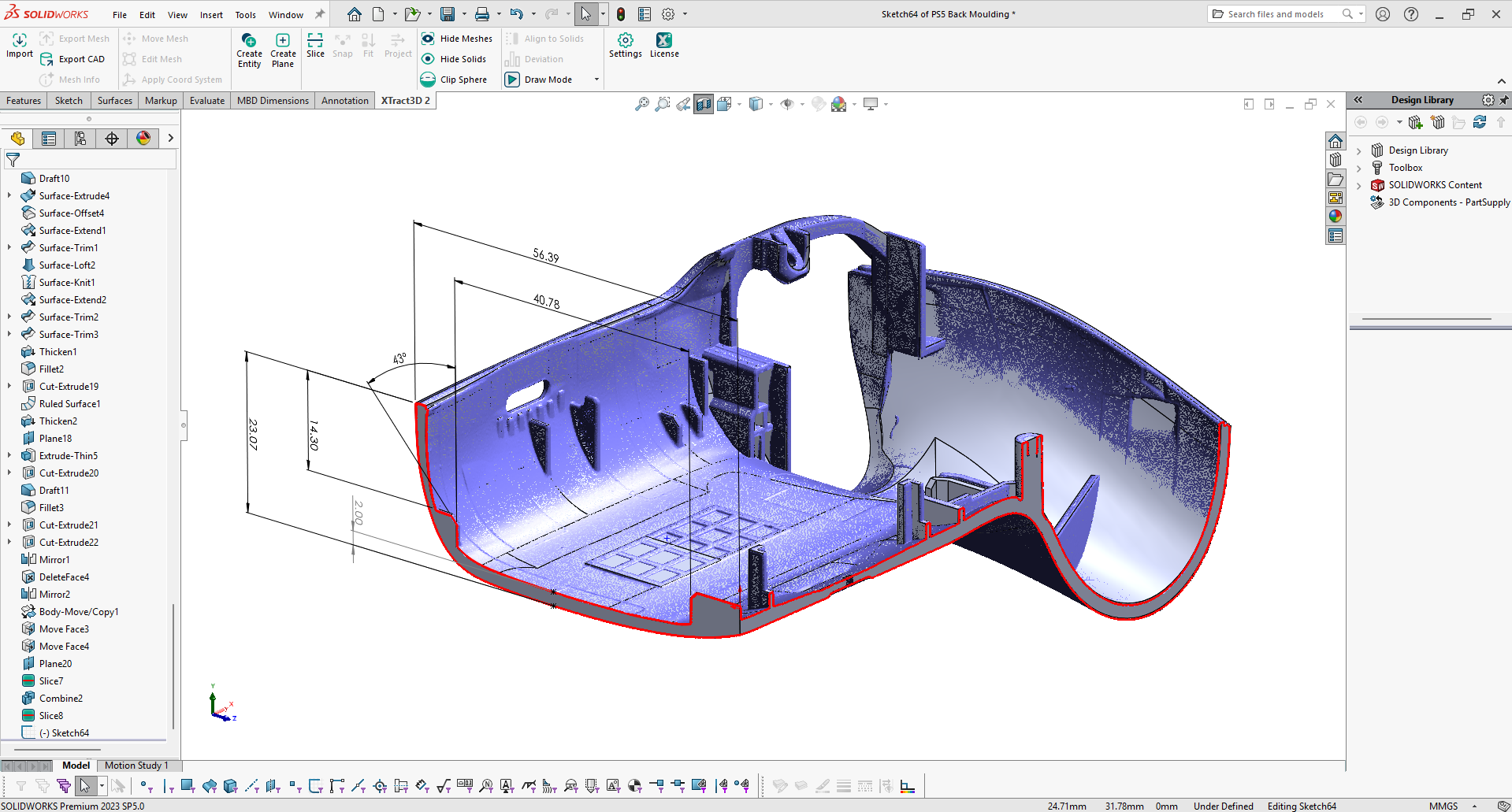

3D scanning in an array using multiple HDI Compact 3D scanners.

Automation and Quality Inspection

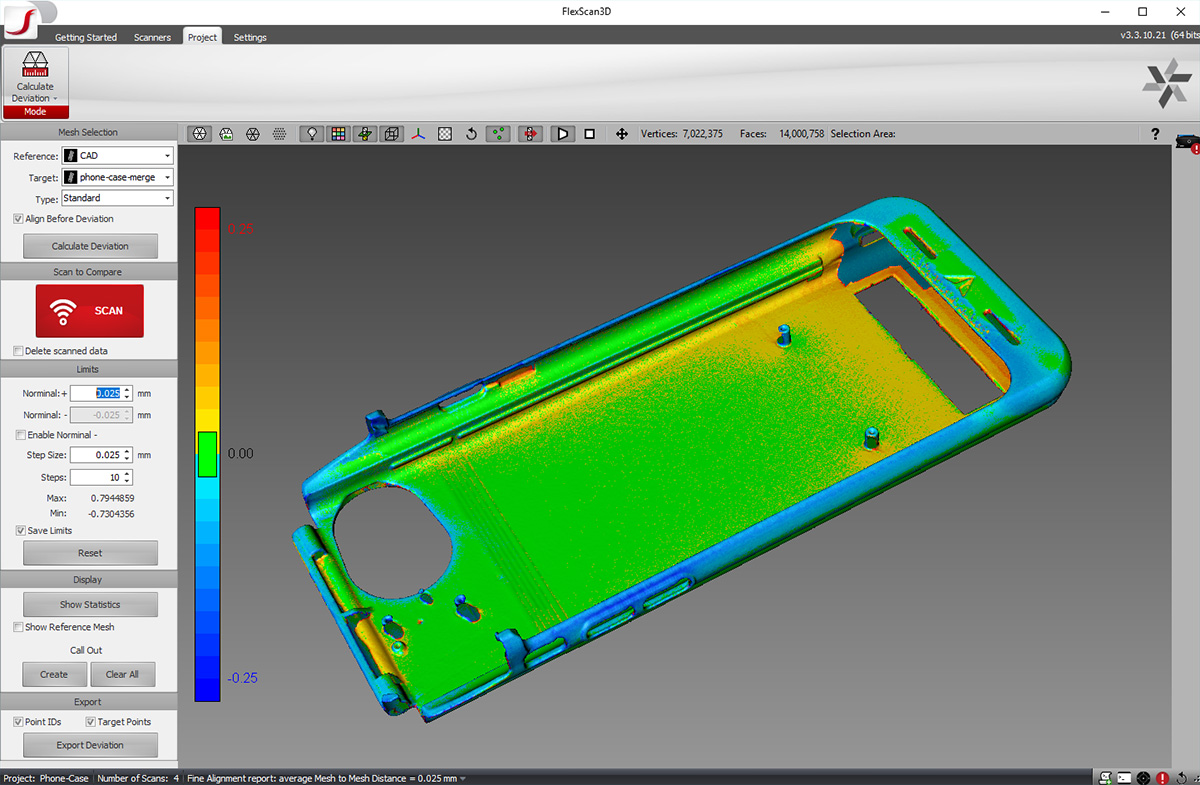

The use of 3D scanning for inspection applications is growing as more manufacturers are adopting factory automation to maximize efficiency. As more products are being manufactured through automation, there is an equal need to automate the inspection process to prevent bottlenecks. This year, we expect to see more 3D scanning software packages offer comprehensive automated analysis tools to completely automate the scan-to-inspect workflow.

A deviation analysis between a CAD model and merged scan data inside FlexScan3D

-

There’s is a growing need to use 3D scanners for robotic vision and guidance as well as for AI applications

To facilitate factory automation, the HDI Compact 3D scanner is compatible with a robotic arm.

From large robotic arms to wheeled vehicles, there is an ever increasing need for robots to accomplish complex tasks. One way or another, robots need robotic vision and guidance in order to gather information and interpret the world. 3D scanners can give them the information they need to understand its environmental conditions to go about their business of performing tasks and interacting with the things around us.

More often than not, traditional 2D cameras do not return enough information for these kinds of complex tasks while full 3D sensors and cameras can fulfill this need. 3D scanners, as they become faster and more capable, will become the choice as the “eyes” for robots.

Robotic Vision and Guidance Example

For Pick and Place/Bin Picking applications related to factory automation, 3D scanners guide robots to grab parts that are randomly placed in a bin. They help robots position parts correctly in the right orientation on a moving conveyor belt. Working together, they provide the speed, flexibility, and consistency that is required to automate the manufacturing process.

How 3D Scanning Evolved With the Introduction of AI

Traditional applications involving 3D scanning technologies mainly relate to taking measurements and someone has to do something with the data in order for it to be useful. With the popularity of Artificial Intelligence (AI) on the rise, computer/robots are becoming more and more capable of perform tasks that normally require human intelligence, such as visual perception and making decisions.

Traditional applications AI applications It’s about measuring objects. It’s about classifications. The computer automatically makes complicated decisions based on information gathered by the 3D scanner. Example: Ability to take measurements of an apple but the computer doesn’t know it’s an apple. Example: The computer has the ability to classify it’s an apple using the measurements collected by the scanner. For authentication purposes, iPhone Face ID uses a structured-light 3D scanner for facial recognition to unlock the phone. Adaptive recognition uses AI (Apple refers to it as advanced machine learning) to recognize changes in facial appearance. Even if you wear accessories, it’s still able to recognize it’s the same person.

Source: Screenshot from Apple website

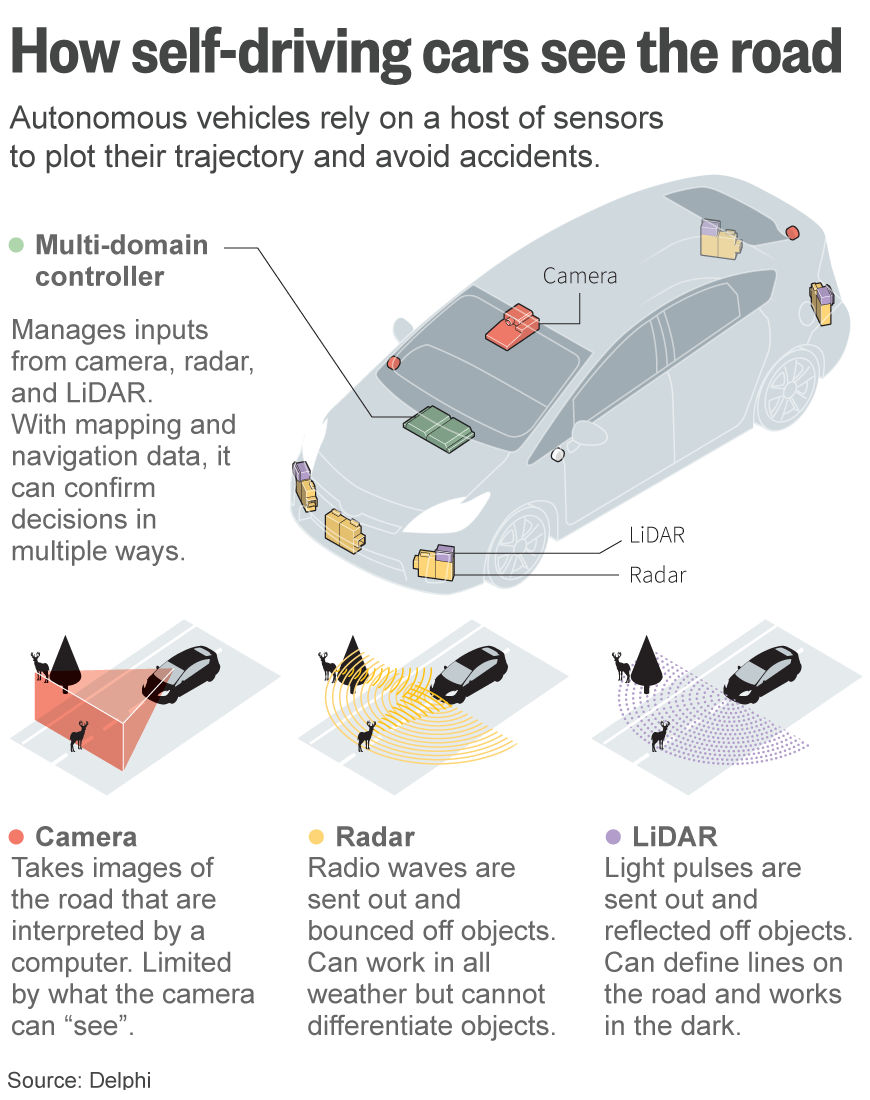

Self-driving cars might still be in experimental stages, but the ultimate goal is to use a host of sensors (including LiDAR 3D laser scanner) to gather information. The computer uses this information to make important decisions including staying on marked roads, preventing the vehicle from hitting objects, and avoiding other accidents.

-

The Features of Professional 3D Scanners Trickle Down To Consumer 3D Scanners To Breed A New Category

Consumer 3D printing was the catalyst that fueled consumer 3D scanning.

A few years ago, during the height of the 3D printing buzz, we saw a number of low-cost consumer 3D scanners entered the marketplace. While these scanners were cheap, they were designed for hobbyists or prosumers. Low-cost consumer 3D scanners were unfit for commercial use. The workflows were not that user-friendly, the accuracy was low, and the resolution was poor for anything other than novelty 3D prints.

As time passes, we’re seeing more and more professional level features trickle down to consumer and prosumer grade 3D systems to spark a new category—low-cost professional 3D scanners. While they are still a long way from being metrology-grade 3D measurement devices, they are perfectly fine for a number of basic reverse engineering, lightweight 3D inspection, and computer vision applications that don’t require high accuracy and resolution. They are also good as a proof of concept. It’s a less costly way to see if implementing 3D scanning into the operation would work well before heavily investing in a more expensive system.

What 3D scanning trends do you see this year?