Hey there! Have you ever wondered how modern technology captures the intricate details of a tiny insect or maps out vast historical artifacts in minutes? Well, the hero behind these feats is none other than the 3D scanner. But it’s not just about having any scanner; it’s about having the right scanner.

That’s why comprehending the difference between accuracy and resolution in 3D scanning metrology is crucial to understanding your needs so you can choose the right product for them. Let’s explore this puzzle together to discover why these little details are big deals!

3D Scanning vs Traditional Measurement Methods

Remember the old-school calipers and micrometers in your grandpa’s tool shed, or the sophisticated GPS systems and Coordinate Measurement Machines (CMMs) used in industrial settings? Let’s take a closer look at those retro methods and analyze why many industries have switched to 3D scanning technology, which is more expensive and very niche.

The Traditional Measurement Methods Cons

These tools have long been staples for precise measurements, each tailored for specific tasks — from simple distance measuring with calipers to the high precision of CMMs in manufacturing. However, sometimes, even old but gold solutions can’t fight the wheel of progress.

Precisive, But For High Skilled

Calipers and micrometers demand the delicate balance of an engineer, while CMMs, Total Stations, and GPS receivers call for the precision of a seasoned navigator.

Well, It’s Time-Consuming

Time isn’t just a factor in any measurement — it’s the currency. The deliberate and cautious pace at which these tools operate makes them increasingly archaic in a fast-paced world.

Also Needs Maintenance Costs

Like cherished antiques, traditional measuring tools come with a ledger of maintenance costs. Their need for continual care and calibration can add up to a significant total over time.

And Finally, Expertise Required

Embarking on the use of these tools is an odyssey of learning — a journey through the measurement intricacies that demands a comprehensive understanding and seasoned experience.

Comprehensive Benefits of 3D Scanning Metrology

Picture stepping into the world of 3D scanning metrology, where measurements are made without physical touch and dimensions are captured with exact precision. This is the domain where thousands of data points are gathered in a blink, bringing complex shapes and complex patterns into digital clarity. With 3D scanning, efficiency is paramount, versatility is a given, and maintenance is simplified, democratizing precision and opening doors to innovation across sectors.

Fast & Furious

The swift nature of 3D scanners reshapes our concept of measurement. Objects are digitized in mere moments, charting a new course for operational efficiency.

Non-Contact

3D scanning excels with its non-contact approach, preserving the integrity of the scanned subject, and making the person an unobtrusive observer rather than an intrusive examiner.

Dozens of Measurement Points

The bounty of data points that 3D scanning metrology gathers wins over the limited scope of traditional methods, ensuring no nuance is neglected.

Consistency Is a Must

With 3D scanning, consistency isn’t just an objective—it’s a guarantee, pivotal in managing complex cases with precision and confidence.

No More Human Error

3D scanning minimizes human error, as the technology supports the user and significantly narrows the margin for mistakes.

Smooth Learning

3D scanning metrology touts a user-friendly learning curve that invites users to quickly adapt, regardless of their previous experience with traditional measurement tools.

More User-Friendliness

With interfaces designed for ease and intuition, 3D scanners are as approachable as they are innovative, encouraging use in the field, the lab, or the studio with equal comfort.

Accuracy vs. Resolution in 3D Scanning: Key Differences Explained

Let’s clear up some confusion. When diving into the world of 3D scanning metrology, two terms frequently pop up that can dramatically influence the outcome of your projects: resolution and accuracy. Both play essential roles but cater to different aspects of scanning. Let’s unwrap these terms with a dash of fun and plenty of real-world examples to see how they impact everything from dental implants to dinosaur bones!

What Is Resolution

Imagine you’re zooming in on a photograph of your favorite beach: the more you zoom, the more details like the individual grains of sand emerge. In 3D scanning metrology, this is resolution: the level of detail the scanner can capture. High resolution allows the scanner to identify the smallest details, akin to having superhero vision.

What Is Accuracy

Consider sketching your neighborhood from memory. How accurate is it compared to the real layout? Accuracy in 3D scanning refers to the precision in capturing an object’s exact dimensions and shape, ensuring the digital model matches the physical world perfectly, which is crucial for applications from aerospace to fashion.

Healthcare & Dental Use Case Examples

Precision is essential in healthcare and dentistry. Take the creation of a dental crown, for example. Dentists rely on the high accuracy of 3D scanners like the Polyga S1 to ensure a perfect fit alongside adjacent teeth. The Polyga S1, made with structured light technology, captures detailed textures of the tooth surface. This enables the creation of crowns that closely mimic the natural look and feel of teeth. This precision not only improves patient outcomes but also enhances the aesthetic integration of the prosthesis.

Historical Preservation & Archeology Use Case Examples

Imagine an archaeologist using high-resolution 3D scanning to explore ancient ruins or delicate fossils. These scanners capture every detail, creating precise digital twins for indefinite study and preservation. Tom O’Mahoney’s work, including the first 3D scan of a human fossil and a digital reconstruction of “Lucy,” exemplifies this technology’s ability to make historical artifacts accessible and vivid, turning them into exact replicas of items centuries-old. This use of 3D technology in archaeology not only preserves our cultural heritage but also allows us to interact with history from anywhere in the world.

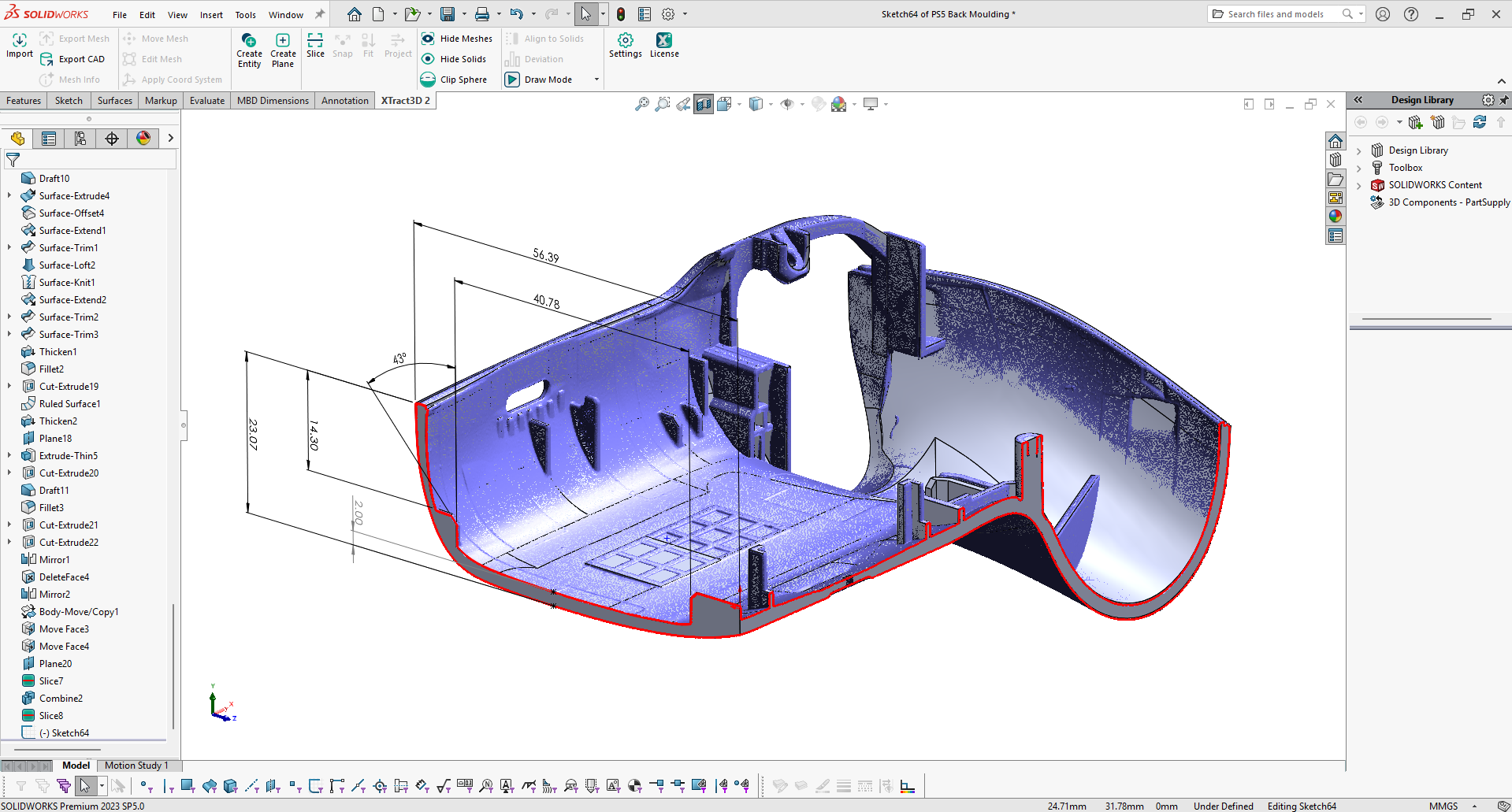

Manufacturing Use Case Examples

As an example of the manufacturing world, let’s take a car factory. Precision is crucial for components like pistons fitting perfectly within engine blocks, preventing operational issues such as rattles. High-resolution 3D scanners, essential for capturing intricate dashboard textures, ensure the final products are both functional and aesthetically pleasing.

Technologies like the Polyga Compact S1 Pro Wide, highlighted for its accuracy and durability, are indispensable in modern manufacturing processes. These advanced scanners contribute significantly to manufacturing efficiency and product quality.

Practical Applications: Varied Types of 3D Scanning Measurement Issues Require Different Solutions

Most scanning applications require a mix of minimum accuracy and resolution. Scanners with high accuracy often have lower point spacing and vice versa. In one example, a CMM ( coordinate-measuring machine) measures the geometry of physical objects by sensing discrete points on the surface. While each point is very accurate, there is an extremely limited number of points, which makes it great for measuring geometric mechanical objects. However, simultaneously, you will struggle with measuring objects requiring high resolution, like organic surfaces as a human face.

In another case, you may want higher resolutions but not need super high accuracy. An example is the 3D scanning of cultural artifacts. You don’t need the highest accuracy in the scan, but you do want a lot of points so that you can clearly see the detail on the objects.

Future Trends in 3D Scanning Metrology

As we skate into the future of 3D scanning metrology, the landscape is driven by smarter technology and the ever-growing demands of industries from aerospace to archaeology. Insights from the Verified Market Reports highlighting how 3D scanning evolves, reflecting its increasing maturity and broader application in various sectors.

AI Takes the Wheel

Imagine a 3D scanner with a brain powered by artificial intelligence (AI). This is no Sci-Fi; it’s transforming 3D scanner metrology. AI in 3D scanners acts like a tireless assistant, making real-time adjustments and enhancing data quality instantly, even correcting errors on the fly. This innovation speeds up scanning and makes it more intuitive, reducing time spent on settings and increasing focus on creative tasks.

Portability Reaches New Heights

The future of 3D scanning emphasizes more than just compact size; it’s about merging advanced functionality into travel-ready formats. Modern 3D scanners are crafted to be highly efficient and versatile, perfect for any setting — from the peaks of the Himalayas to tight spaces within machinery. These devices, including our portable handheld scanner Polyga H3, are designed for professionals to easily transport and use spontaneously, ensuring they are always ready to capture detailed data in any environment, from remote digs to active engineering sites.

Polyga at the Forefront

As trends evolve, Polyga is at the forefront, actively working on integrating AI into our scanners to enhance their smartness and responsiveness. We’re also improving their portability, ensuring our products are easy to transport and effective under diverse conditions. Soon, 3D scanning will be as ubiquitous and straightforward as using a digital camera, with AI providing instant insights and solutions. It’s an exciting time in 3D metrology, as we leap into a future filled with boundless possibilities. Get ready for an exciting journey into the next generation of 3D scanning!

FAQ

Q1: How does 3D measurement work?

3D measurement scanner involves capturing the physical objects using various technologies that create a digital model. This process generally includes scanning an entity from multiple angles with a 3D scanner, which collects data points from the surface. These points are then used to reconstruct a 3D model that accurately replicates the object’s shape and size.

Q2: What are the types of 3D measurement technologies?

There are several types of 3D scanner measurement technologies, each suited for different applications:- Laser Scanning: Uses laser light to capture precise measurements quickly.

- Structured Light Scanning: Projects patterns onto a thing and measures deformations to capture its shape.

- Photogrammetry: Uses multiple photographs taken from different angles to create a 3D model.

- Contact Probing: Involves physically touching a thing with a probe to measure its dimensions. This method is often used for highly accurate internal measurements.

Recap: Exploring 3D Scanning With Polyga

What a ride it’s been! We’ve delved into the nuances of resolution and accuracy and seen how AI and portability revolutionize 3D scanning. Clearly, this field is more than about capturing images — it’s about helping companies reach their business goals, unlock industry capabilities, reduce time to market, and achieve 2x-4x cost savings. At Polyga, we’re not just participants but pioneers, constantly innovating to push the boundaries of 3D scanning. Whether you’re working with custom prosthetics, engineering aerospace components, or preserving historical artifacts, Polyga ensures you effortlessly achieve the best results.

Contact us if you need help with your 3D scanning challenges. Let’s capture the world together, one precise scan at a time!