3D Scanner FAQ – Most Frequently Asked 3D Scanner Questions

3D Scanner Introduction

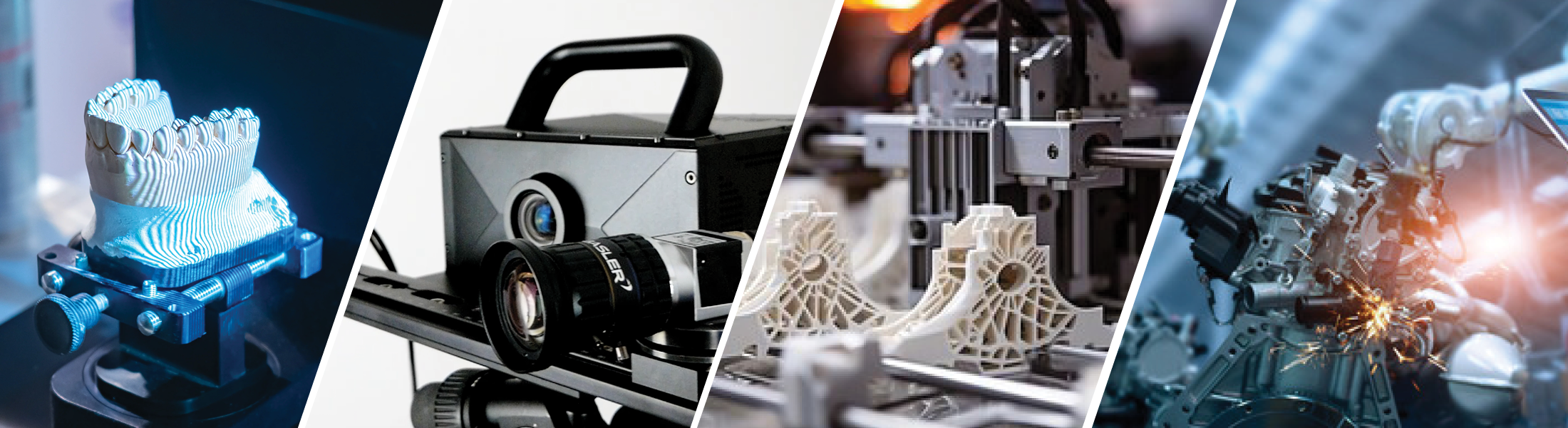

Welcome to our comprehensive 3D scanner FAQ page, where we demystify the world of 3D scanning technology. If you’re intrigued by the possibilities of 3D scanning or considering investing in a 3D scanner, you’ve come to the right place. In this guide, we’ll explore everything you need to know about 3D scanners, their applications, types, accuracy, and much more. Whether you’re a seasoned professional or a curious enthusiast, our goal is to provide you with the answers you seek and empower you to make informed decisions in the exciting realm of 3D scanning.

What is a 3D Scanner?

3D scanning is the process of capturing the three-dimensional shape and appearance of real-world objects or environments and creating a digital representation or 3D model from scan data. A 3D scanner is a device that enables you to take a physical object, scan it into a digital format, and work with the digitized 3D model in a digital 3D enviroment. If paired with a 3D printer; a 3D scanner expands the capabilities of a 3D printer, allowing you to replicate the shape of almost any object.

Can I use my Phone as a 3D Scanner?

Yes, you can use your smartphone or an Iphone as a 3D scanner, but the results may not be as accurate or detailed as those obtained with dedicated 3D scanners. There are several apps available for smartphones that use the device’s camera and sensors to create 3D scans of objects or environments. These apps typically work by taking a series of photos or capturing depth data and then processing that information to generate a 3D model. Here are some points to consider if you want to use your phone as a 3D scanner:

- Quality: The quality of 3D scans produced by smartphone apps can vary widely depending on the app, the phone’s camera and sensor capabilities, and the lighting conditions. You may get better results with newer and higher-end smartphones with advanced camera systems.

- Ease of Use: Smartphone 3D scanning apps are often designed to be user-friendly and accessible, making them a good choice for beginners.

- Portability: Using your smartphone as a 3D scanner offers the advantage of portability, allowing you to scan objects or environments on the go.

- Limitations: Smartphone 3D scanning may not be suitable for capturing highly detailed or complex objects. The accuracy and level of detail in the scans may be limited compared to dedicated 3D scanners.

- Portability: Using a smartphone as a 3D scanner is cost-effective if you already own a compatible device. Many 3D scanning apps are available for free or at a low cost.

Yes, you can use your smartphone as a 3D scanner, but the results may not be as accurate or detailed as those obtained with dedicated 3D scanners. There are several apps available for smartphones that use the device’s camera and sensors to create 3D scans of objects or environments. These apps typically work by taking a series of photos or capturing depth data and then processing that information to generate a 3D model.

How Much Does a 3D Scanner Cost?

The cost of a 3D scanner can vary widely depending on several factors, including the type of scanner, its capabilities, and the brand. Here’s a rough breakdown of the cost range you can expect for different types of 3D scanners: How structured-light 3D scanners work?

- Handheld 3D Scanners: These are portable and often used for smaller objects or for scanning in the field. Prices can range from a few hundred dollars to several thousand dollars, with high-end models reaching into the tens of thousands of dollars.

- Desktop 3D Scanners: These are designed for scanning objects on a desk or workbench. Prices typically start in the range of $1,000 to $5,000, but more advanced models with greater accuracy can be more expensive.

- Industrial 3D Scanners: These are high-precision scanners used in various industries, including manufacturing, aerospace, and healthcare. The cost of industrial 3D scanners can range from $10,000 to $100,000 or more, depending on the complexity and capabilities of the scanner.

- Professional 3D Scanners: These scanners are suitable for professional use in fields like architecture, archaeology, and product design. Prices generally start around $7,000 and can go up to $25,000 or more for advanced models.

- Medical 3D Scanners: Specialized 3D scanners for medical applications, such as dental or orthopedic scanning, can vary widely in cost. They can range from a few thousand dollars to tens of thousands of dollars.

- Large-Scale 3D Scanners: These are used for scanning large objects or environments, such as buildings or landscapes. Prices for large-scale scanners can range from tens of thousands to hundreds of thousands of dollars.

How Can I Scan 3D for Free?

Here are some points to consider if you want to use your phone as a 3D scanner:

It is possible to 3D scan for free by using your smartphone’s camera and 3D scanning apps like 3D Scanner App or by using free photogrammetry software with a regular digital camera to create 3D scans from photos. Some web-based 3D scanning services may also offer free options.

Are 3D Scanners Good?

The quality and usefulness of a 3D scanner depend on several factors, including your specific needs, the type of scanner, its accuracy, and how well it meets your requirements. Here are some considerations to determine if a 3D scanner is “good” for your purposes:

- Accuracy: A “good” 3D scanner should provide the level of accuracy required for your intended application. Different scanners have varying levels of precision, so it’s essential to match the scanner’s accuracy with your project’s demands.

- Resolution: Consider the scanner’s resolution, which determines how much detail it can capture. High-resolution scanners are crucial for capturing fine details, while lower-resolution scanners may suffice for less detailed objects.

- Speed: Evaluate the scanning speed, especially if you need to scan multiple objects quickly or capture real-time data. Some scanners are faster than others, but this may affect their accuracy.

- Portability: Determine if the scanner’s portability aligns with your requirements. Some applications may benefit from a portable, handheld scanner, while others may require a more stationary setup.

- Ease of Use: A good 3D scanner should have user-friendly software and straightforward calibration and setup processes. Complex or challenging-to-use scanners can slow down your workflow.

- Compatibility: Ensure the scanner is compatible with your existing hardware and software. Compatibility issues can hinder your ability to work efficiently.

- Cost: Consider your budget and how it aligns with the scanner’s capabilities. High-end 3D scanners with advanced features tend to be more expensive, while more affordable options may have limitations.

- Application: The suitability of a 3D scanner also depends on your intended application. Some scanners are better suited for specific industries or tasks, such as industrial scanning, medical scanning, or art and design.

- Support and Documentation: A reputable manufacturer or provider should offer good customer support and provide comprehensive documentation and training resources.

- User Reviews and Recommendations: Reading user reviews and seeking recommendations from others in your industry can help you gauge the quality and performance of a particular 3D scanner model.

In summary, whether a 3D scanner is considered “good” depends on its performance in relation to your specific needs and expectations. It’s essential to thoroughly research different models, compare their specifications, and, if possible, try them out before making a decision. Additionally, consider the long-term support and maintenance requirements, as well as the availability of software updates and upgrades for the scanner you choose.

What are the Disadvantages of 3D Scanning?

While 3D scanning offers numerous advantages, it also comes with some disadvantages and limitations that are important to consider. Here are the main disadvantages of 3D scanning:

- Cost: High-quality 3D scanning equipment can be expensive to purchase and maintain. This cost can be a barrier for individuals and small businesses.

- Complexity: Operating 3D scanners and processing the resulting data can be complex, requiring specialized knowledge and training. This complexity can slow down workflows and increase the learning curve.

- Limited Range: 3D scanning technologies have a limited scanning range, which can be a limitation when scanning large objects or environments.

- Scanning Environment: 3D scanners are sensitive to environmental conditions such as lighting and temperature. Suboptimal conditions can lead to inaccurate scans.

- Reflective Surfaces: Shiny or reflective surfaces can be challenging to scan accurately, as they may cause glare or interference with the scanning process.

- Complex Geometry: Very complex or intricate shapes can be difficult to scan accurately, as the scanner may have difficulty capturing all surface details.

- Data File Size: 3D scan data files can be large, which may require significant storage capacity and can slow down data transfer and processing.

- Resolution vs. Speed Trade-off: In some cases, there’s a trade-off between scanning speed and resolution. Faster scans may sacrifice detail, while high-resolution scans may take longer.

Despite these disadvantages, 3D scanning remains a valuable technology for a wide range of applications. Many of these limitations can be mitigated with proper training, equipment selection, and workflow optimization. When considering 3D scanning for a project, it’s essential to carefully assess its advantages and disadvantages to determine if it’s the right solution for your specific needs.

What Can a 3D Scanner Scan?

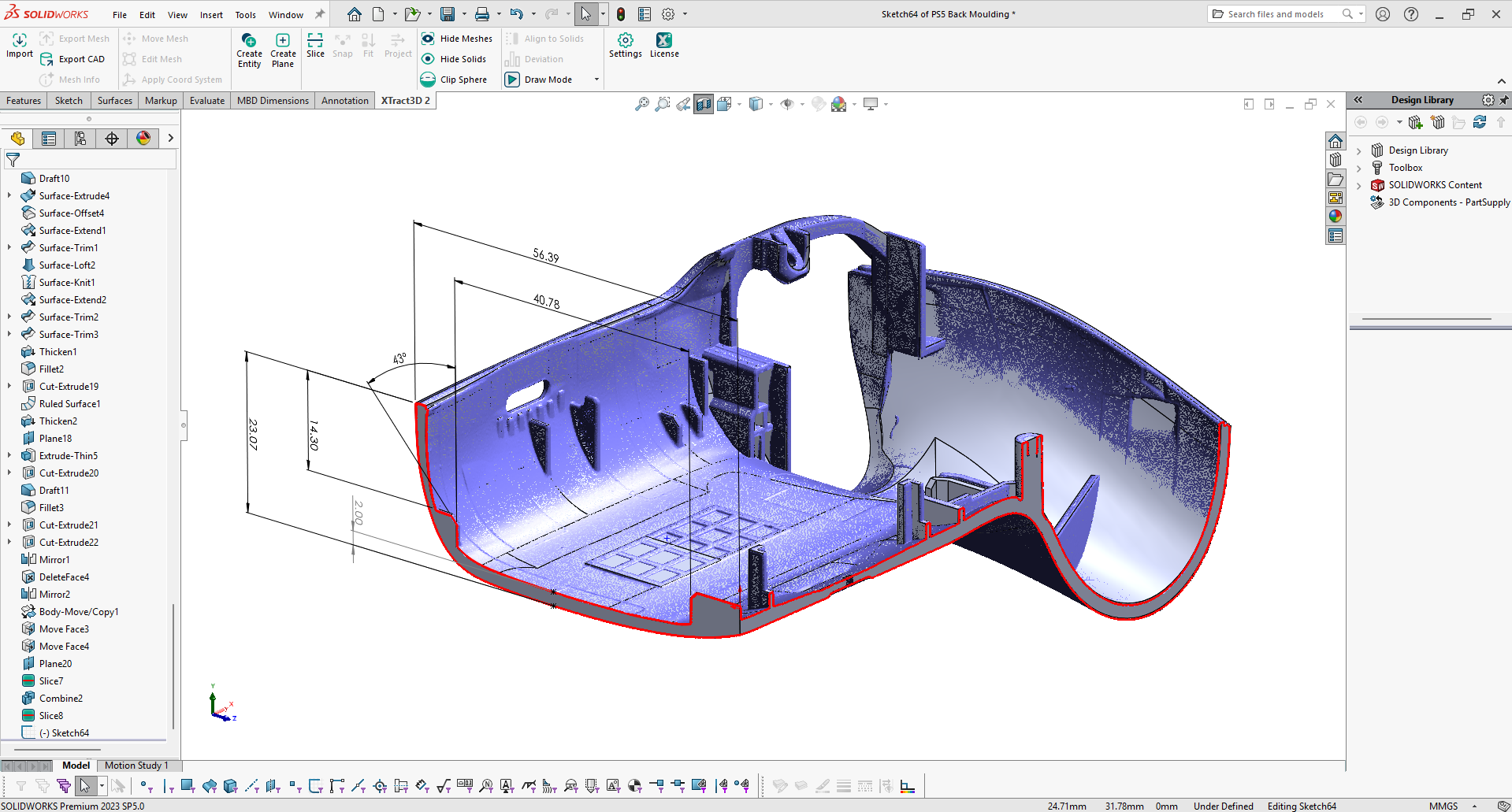

3D scanning is now more popular than ever, people all over the world are embracing the versatile technology easily taking measurements and creating 3D models. The resulting 3D model can be manipulated, analyzed, visualized, and used in various applications. Some common uses of 3D scanner include:

- Manufacturing: Quality control, reverse engineering, and rapid prototyping.

- Design: Creating 3D models for product design, architecture, and interior design.

- Entertainment & Animation: Creating 3D characters, props, and environments for video games, movies, and virtual reality.

- Medical: Capturing 3D data for medical imaging, prosthetics, and orthodontics.

- Heritage Preservation: Documenting and preserving cultural artifacts, sculptures, and historical sites.

- Forensics: Gathering 3D data at crime scenes for analysis and reconstruction.

In terms of objects of different sizes, we have put together a handy article that breaks down different objects sizes you can scan with different kind of 3D scanning hardware. Which 3D Scanner is Right for You?

This FAQ should help provide valuable information to your website visitors about 3D scanners and address some of the common questions they may have. Feel free to check out our “Which scanner is right for you?” article link below to further to match the specifics of your project to the products or services that you require.